Treated Lumber Classifications: What You Need to Know

For a first-time deck builder, knowing what type of pressure-treated (PT) lumber to use can be confusing. The labels at the end of each piece of PT lumber aren’t usually very helpful, either—seemingly random numbers, letters, and phrases like “ground-contact” may not be very clear at first glance.

To make things easier, we’re doing to break down exactly what lumber treatment is, what preservatives are used in the process, and the classifications of treatment types. This guide should help when you’re selecting the materials for your deck or dock.

Note: When handling treated lumber, wear gloves, a face mask, and eye protection. Dispose of treated lumber scraps and sawdust in a landfill; never burn them. These cautionary measures keep you and the environment safe from the preservatives used in treated lumber.

Why Does Lumber Treatment Type Matter?

There’s a common misconception that all treated lumber is created equal, but each kind has its own unique properties and applications. If you want your dock or deck to be safe, durable, and compliant with local building codes, you need to understand the differences between types of pressure-treated lumber.

For example, not all PT lumber is designed to withstand contact with salt water. If you used freshwater-only lumber on an oceanside dock, it would spell disaster in just a few short years or maybe even months. Using improperly treated lumber is bad for the wood, the environment, and your wallet.

So if you’re a homeowner or contractor who isn’t 100% up to speed with the different classifications of treated lumber, let’s break things down.

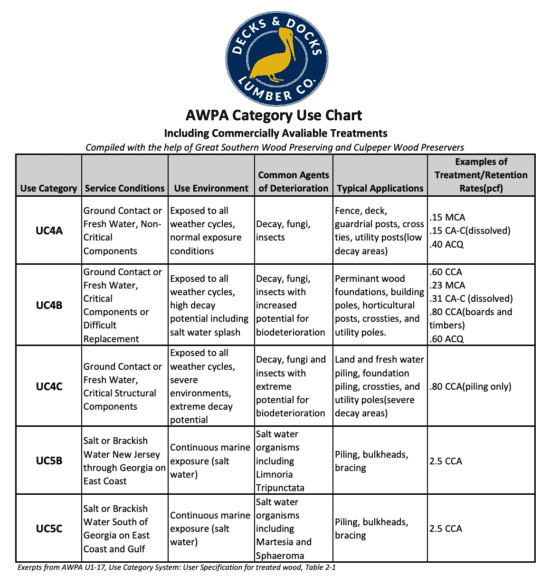

The AWPA Use Category System

The American Wood Protection Association (AWPA) is a non-profit organization that has long set the standards for treated wood used in residential and commercial applications. AWPA Standards are purely informational, but they are often referenced in federal, state, and local building code laws.

The AWPA Standards describe ways to handle wood to maintain its longevity and protect the environment. In these standards, the AWPA classifies wood treatment types depending on where and how they can be used.

The AWPA Use Category system gives contractors and homeowners a simple way to understand and apply AWPA Standards. In the AWPA Use Category system, all types of treated wood can be sorted into categories based on how well it holds up in different applications.

Only a select few categories describe wood treatments that are suitable for marine use. See our chart below to learn what types of treated lumber we carry at Decks & Docks.

Lumber Treatments Approved for Marine Construction

At Decks & Docks Lumber Company, our specialty is all things marine construction. That’s why we only supply lumber categorized as UC4A or greater. Our wood is approved for exposure to water, weather, and for ground contact. Let’s go into why that’s important.

For decks and docks of all kinds, many contractors choose UC4B and UC4C for the decking and framing. Experienced contractors know that you need to have lumber that is certified for “ground contact” or higher for humid, harsh, or near water applications.

These treatments help protect lumber from rot, moisture, and burrowing pests—and to prevent the treatment in your lumber from seeping out into the environment. This lumber can often be used in environments where occasional saltwater contact is likely, such as framing over saltwater. Lumber that isn’t safe for ground contact will wear away faster and may even cause damage to the flora and fauna surrounding it.

If you’re looking for lumber to use in an ocean environment, look for wood that is labeled as “marine grade” or classified as UC5B and UC5C. This indicates that the wood can withstand continuous saltwater exposure. Salty or brackish water is more abrasive than freshwater, so using ground contact-certified lumber is not enough for these settings.

Active Ingredients in Treated Wood: MCA, CA, ACQ, and CCA

Another important acronym to pay attention to on a lumber label is the type of preservative that was used to treat the wood.

To prepare it for harsh marine environments, wood is pressure treated with a combination of water and preservatives to keep pests away and slow the rate of decay. Different preservatives are suited for different applications and types of wood. Let’s go over some of the most common treatments you’ll see in marine lumber.

- MCA (micronized copper azole) and CA (copper azole) – Copper-based preservatives suitable for above-ground, below-ground, and freshwater uses. These treatments penetrate deep into lumber to prevent rot from water exposure and pests.

- ACQ (alkaline copper quaternary) – Contains a quaternary compound including copper and ammonium. ACQ is strong against fungi, insects, and other marine creatures that may damage the integrity of lumber.

- CCA (chromated copper arsenate) – A combination of chromium, copper, and arsenic for maximum protection. Because of its chemical content, CCA is approved for marine construction but not for most residential applications (like in homes, fences, or furniture).

Source: US Forest Products Laboratory

All of these treatments are water-based (as opposed to oil-based). That allows the treatment to fully penetrate lumber while still allowing the application of paint and finish.

Because of the power of each treatment type, you’ll need hardware that won’t rust or wear down the wood. Our selection of hardware is designed to withstand corrosion and complement pressure-treated lumber.

Breaking Down the Lumber Label

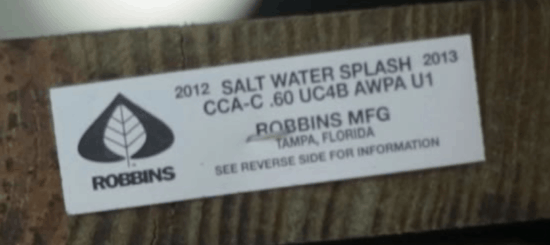

Now that you have a better understanding of the different acronyms used to describe lumber labels, let’s break down the label above.

- CCA-C is the active ingredient—in this case, chromated copper arsenate, type C.

- 0.60 is the lumber’s retention rate, or the amount of preservative used to treat the wood. The higher the retention rate, the lower the biodeterioration rate.

- UC4B is the Use Category. UC4B lumber is suitable for ground contact and contact with freshwater. It is also durable enough to be used for “critical construction” projects, such as utility poles.

- AWPA U1 signifies that the wood has been treated according to AWPA Standards.

Need help? We’re here!

We’re marine lumber experts. You can feel confident that the wood you source from Decks & Docks will be long-lasting and safe to use outdoors.

Lumber treatment can be difficult to understand. If you need help figuring out what type of treated lumber you need for your deck or dock, our experts are available to answer your questions. Just contact us!

- About the Author

- Latest Posts

Brian has worked for Decks and Docks for over ten years. He worked his way up the ladder, started as our Wilmington Branch Manager, opening that store for us in 2013. Brian was then promoted to our first Regional Manager and oversaw six stores before being promoted to our Corporate Office as COO. His vast experience in our industry makes him a valuable asset to the team and to our customers.